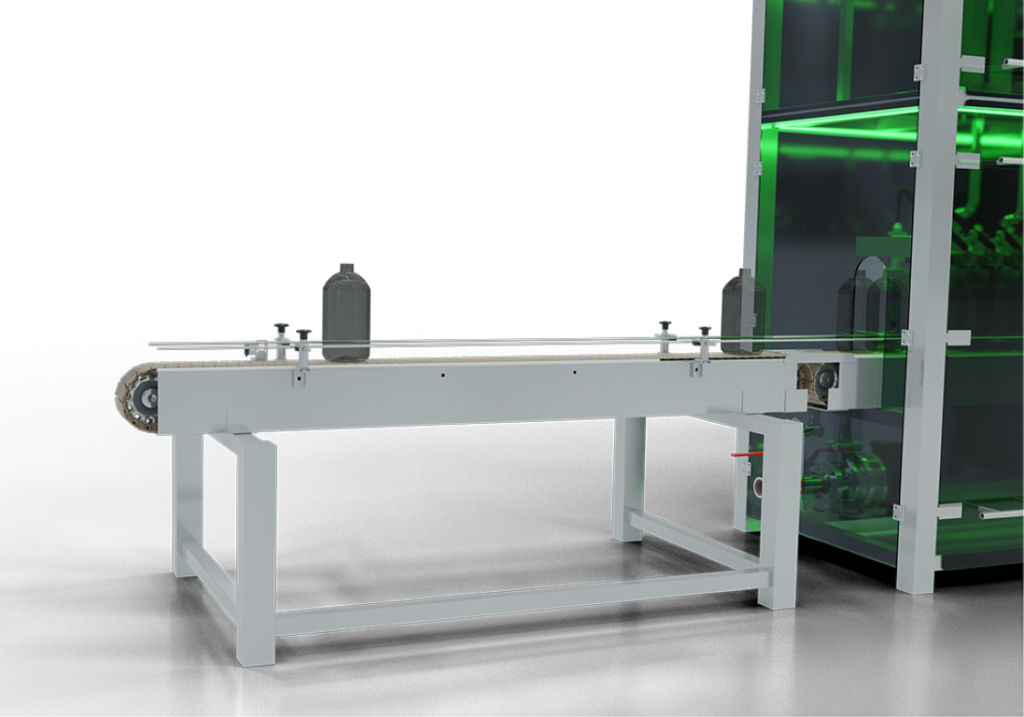

Safety Barrier

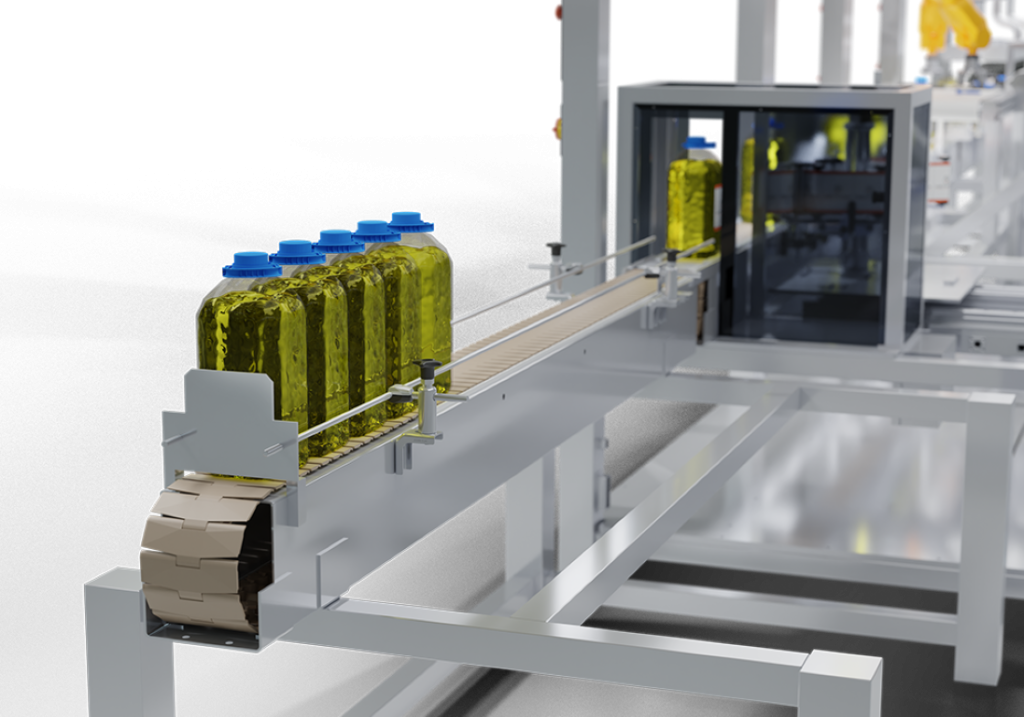

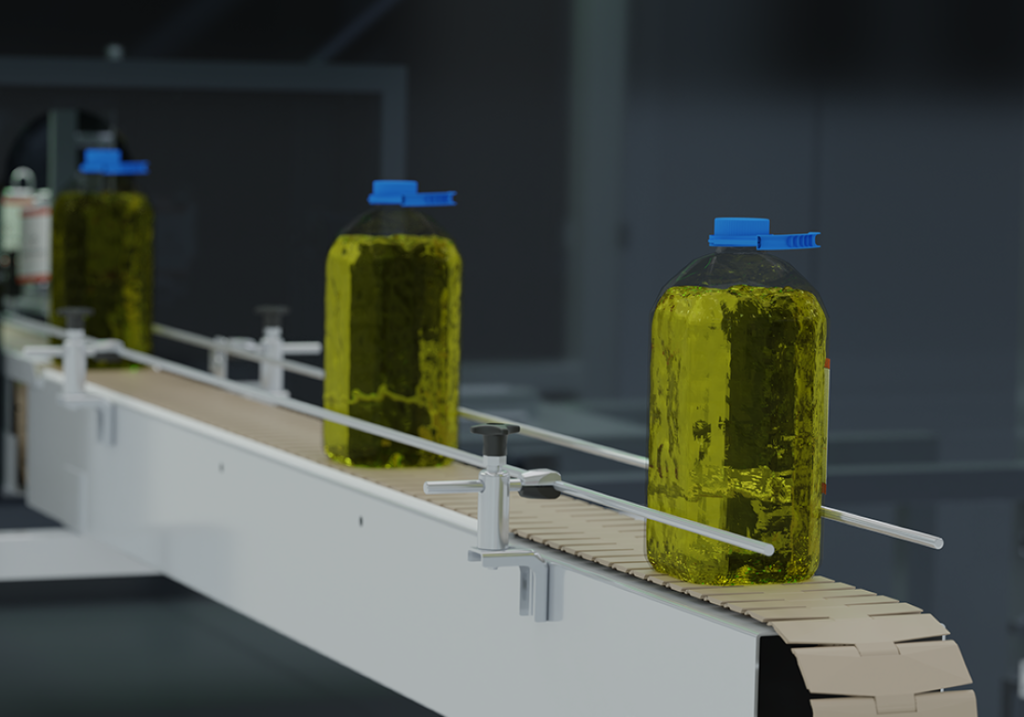

Media Bottle

The machine is designed to handle bottles with dimensions of up to 5 liters but is adaptable to various bottle types. For example, it can accommodate bottles made from:

- PET – for beverages, juices, and similar products.

- HDPE – for detergents, cleaning agents, oil, and similar products.

- PP – for cosmetics, pharmaceutical products, and cleaning agents.

- PVC – for specific packaging needs such as bottles for cleaning agents, chemicals, and medical liquids.

The choice of plastic, as well as the shape and size of the bottle, depends on the type of liquid being packaged, durability requirements, product safety, and the manufacturer’s preferences.

The machine can also include a base, making it suitable for a wide range of bottle types.

Control Screen

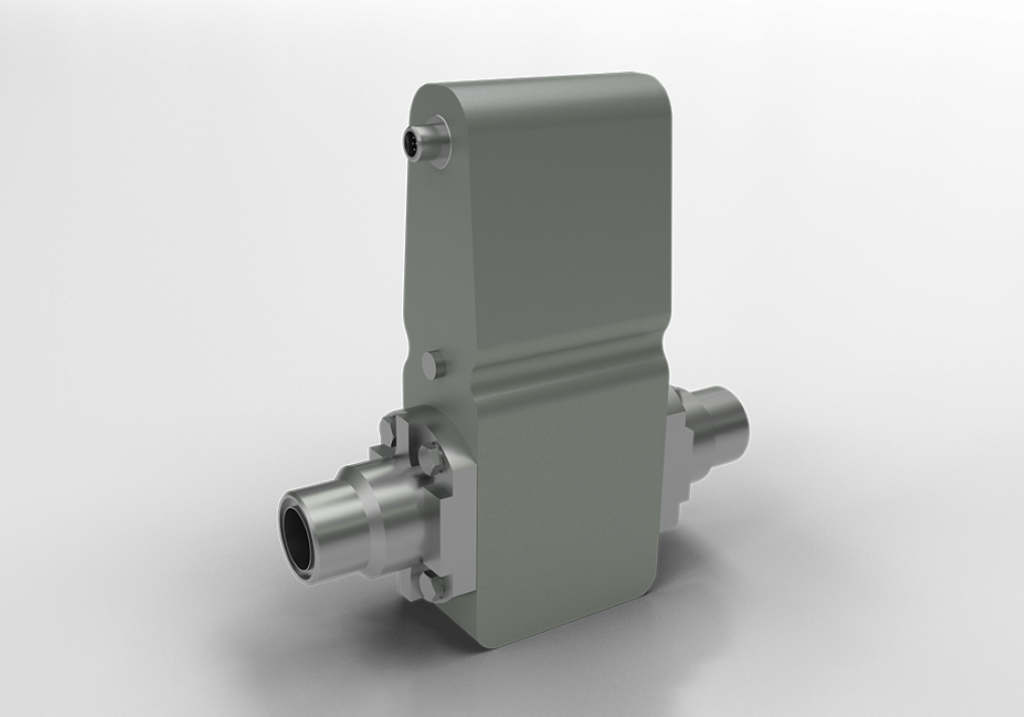

Mass Flow Meter

It is used to measure the mass of a medium/liquid and provides direct information about the mass of the medium/liquid flowing per unit of time (kilograms per second, kg/s), thus enabling automatic monitoring and control of the filling process.

The mass flow meter enables:

- Precise mass measurement, independent of temperature and density.

- Efficient and flexible filling of various media with minimal waste and a high level of control.

Pneumatic Nozzles

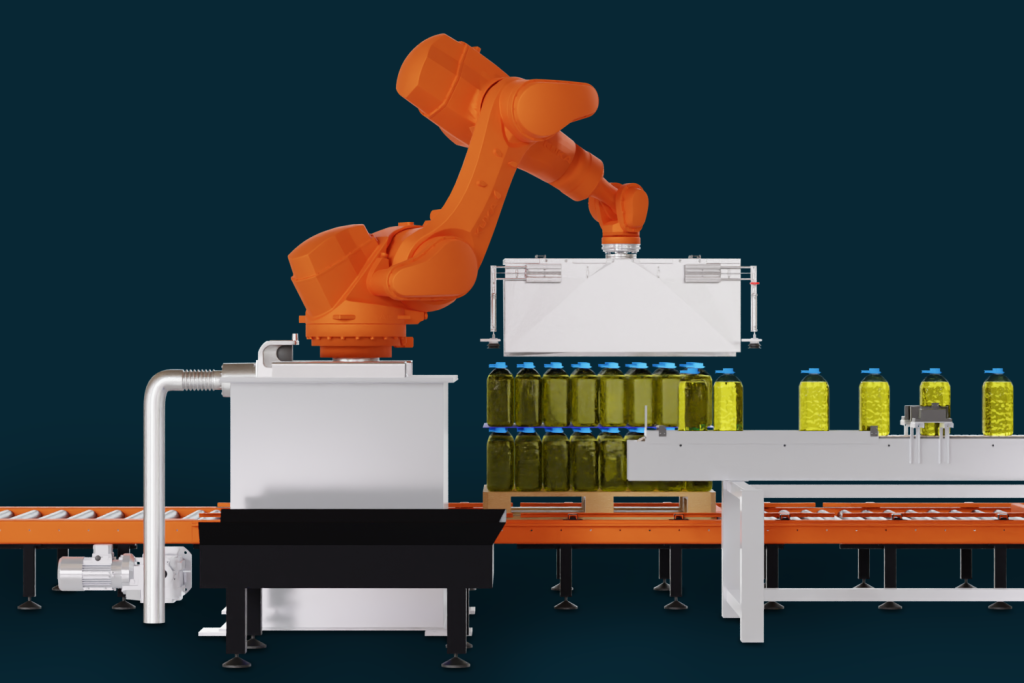

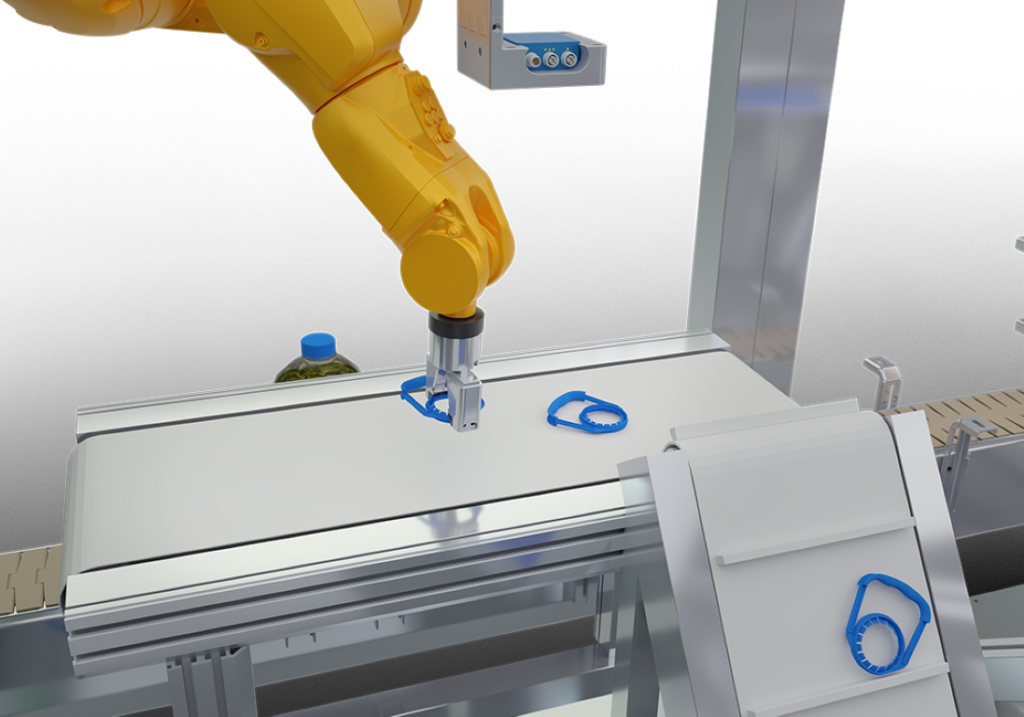

Gripper

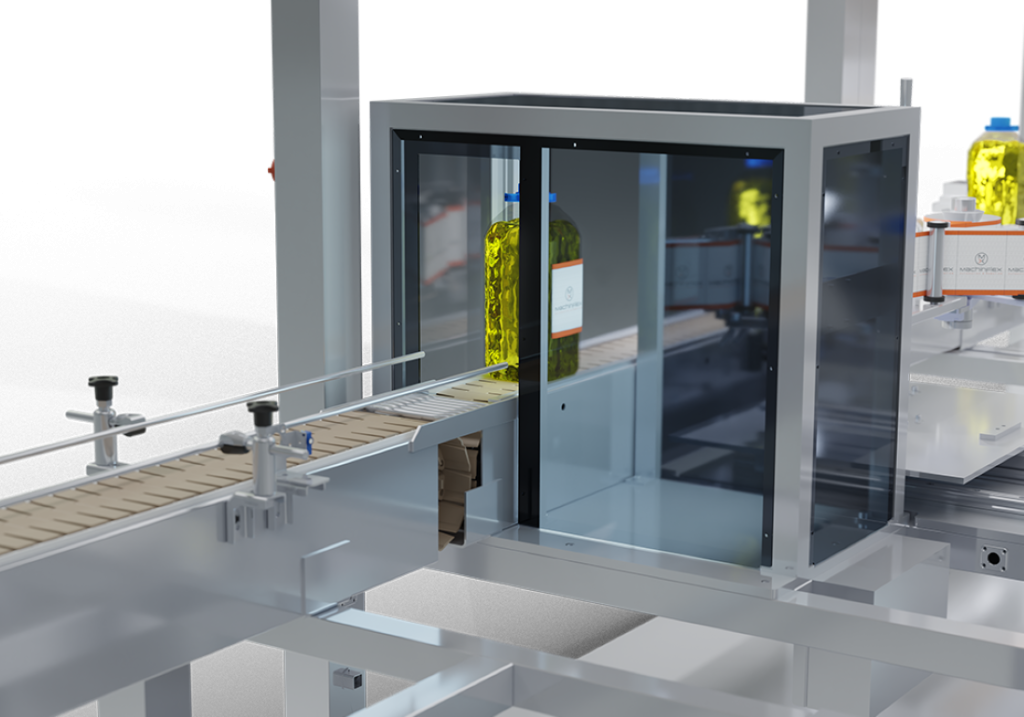

Optical Handle Inspection

Stainless Steel Construction

Optical Inspection

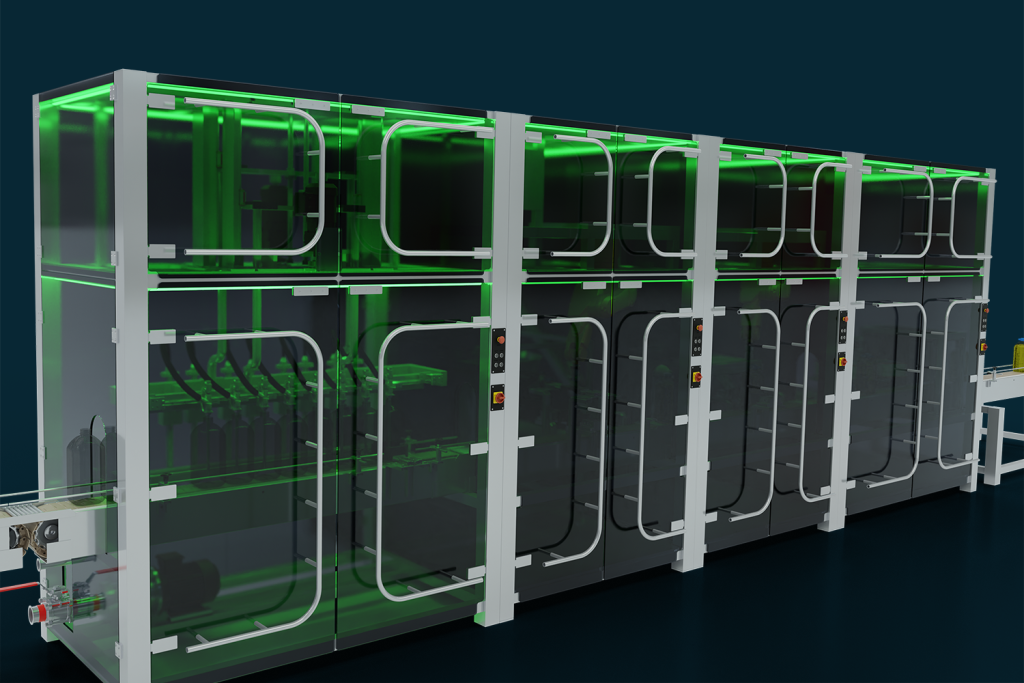

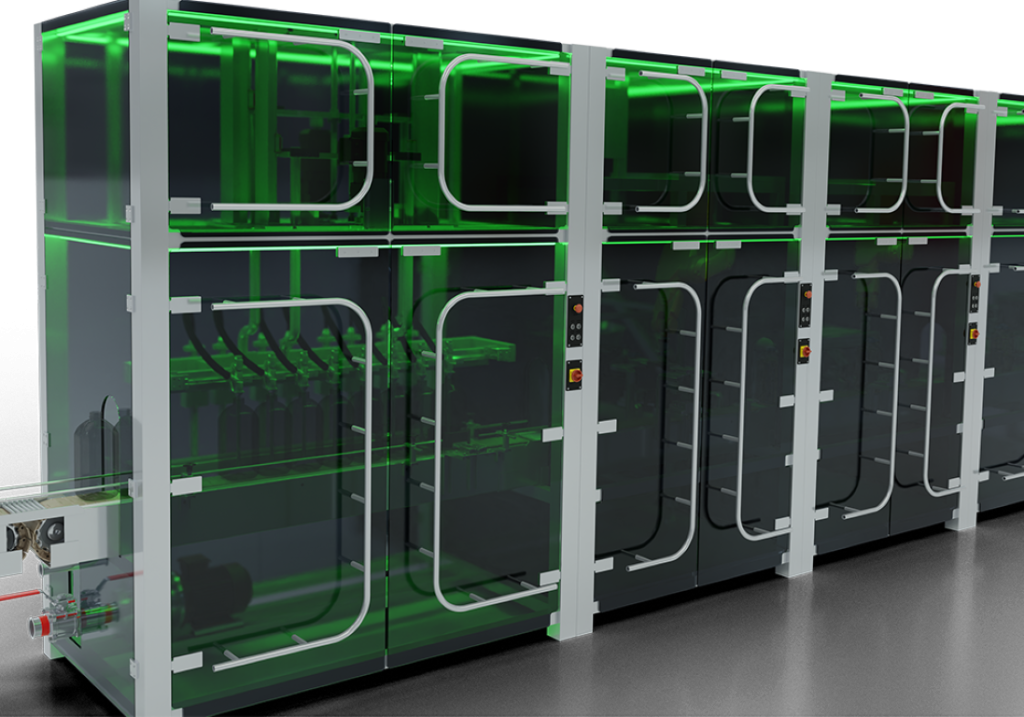

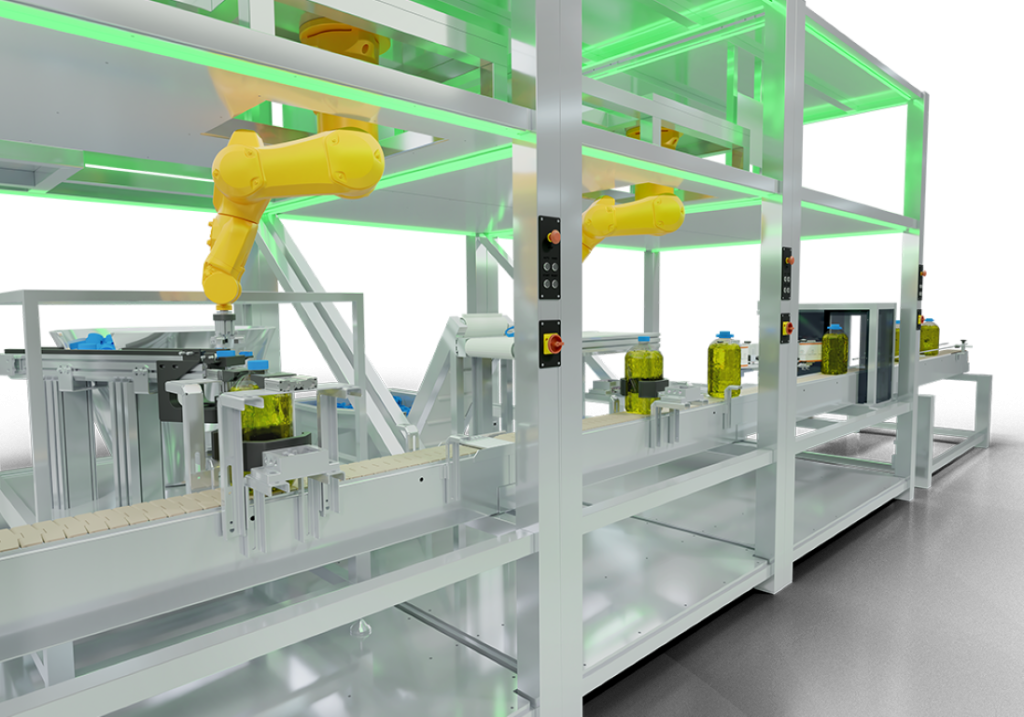

Machine Light Indicator

The LED lighting serves as an indicator for the operator about the machine’s operation.

- Green light: The machine or a segment of it is operating correctly and without issues.

- Red light: The machine or a segment of it is not functioning correctly, or there has been a stoppage/fault.

- White light: The machine’s doors are open.

- Blue light: The machine segment is missing components for operation (e.g., bottle, medium, cap, handle, etc.).

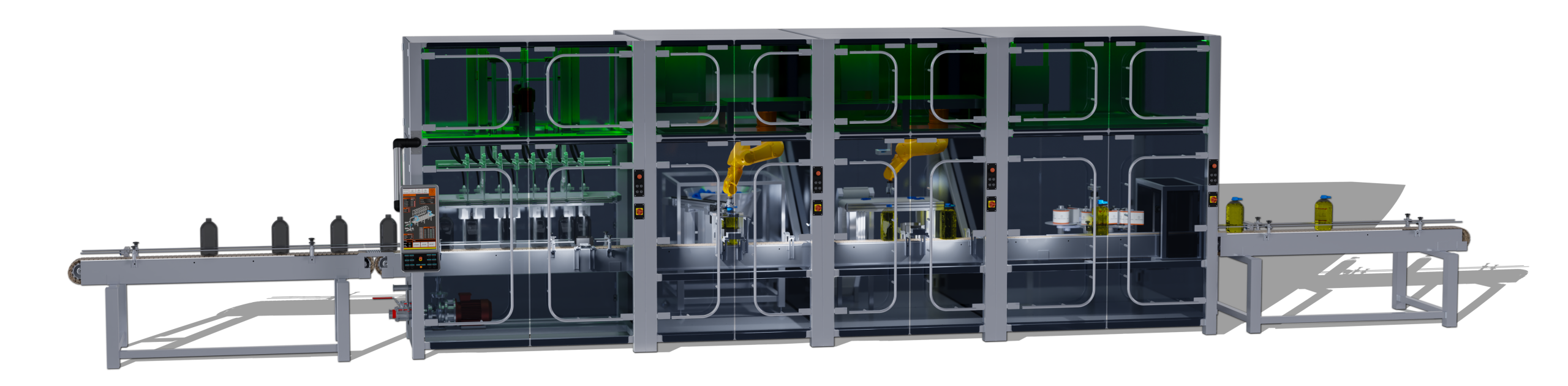

Liquid Media Filling Line XFR 1000

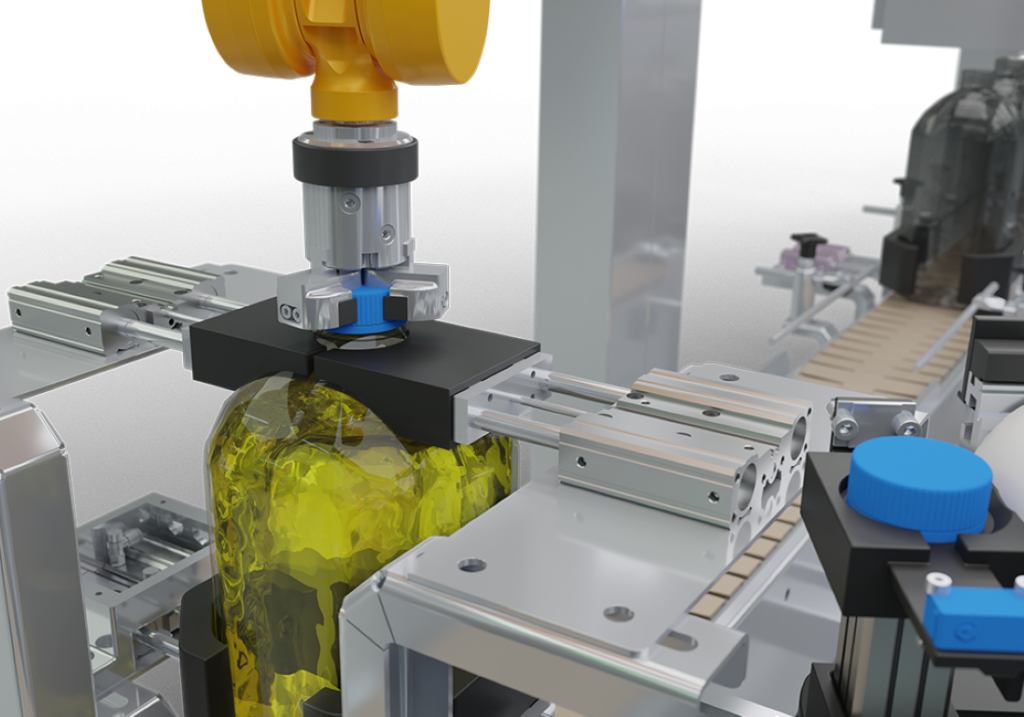

XFR LIQUILOAD – Fast and adaptable for various bottle shapes and liquid viscosities, with expandable nozzles and anti-foaming design.

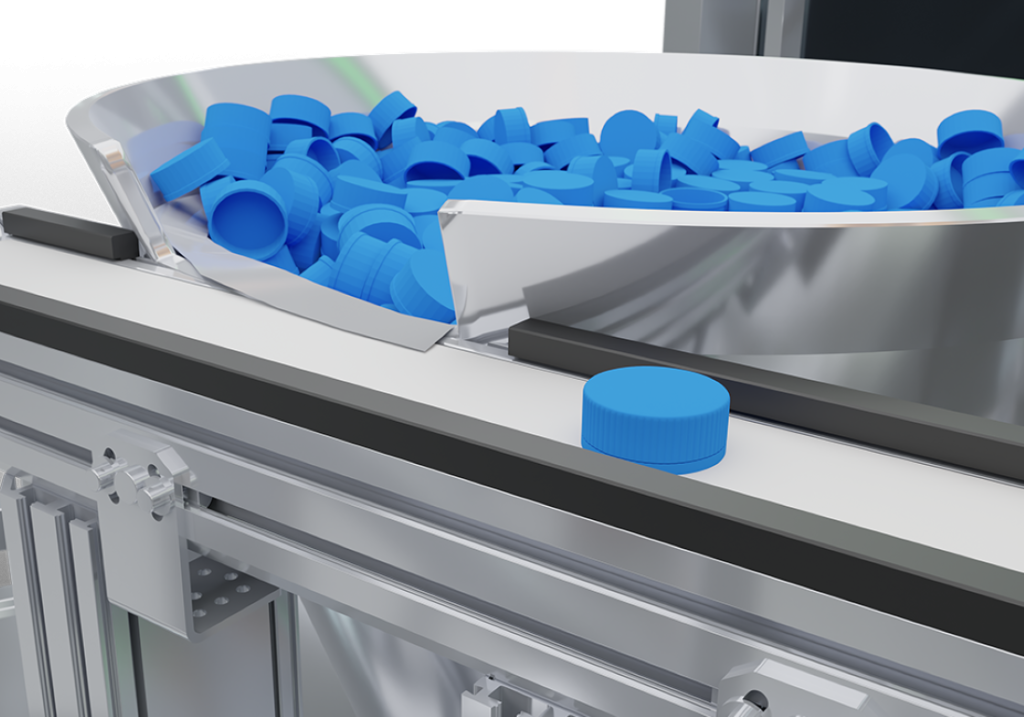

XFR BOTTLELOCK – Fully automated, robotic bottle capping with optical inspection, adaptable to various cap types.

XFR HANDLEGRIP – Robotic handle application on moving bottles with optical orientation verification.

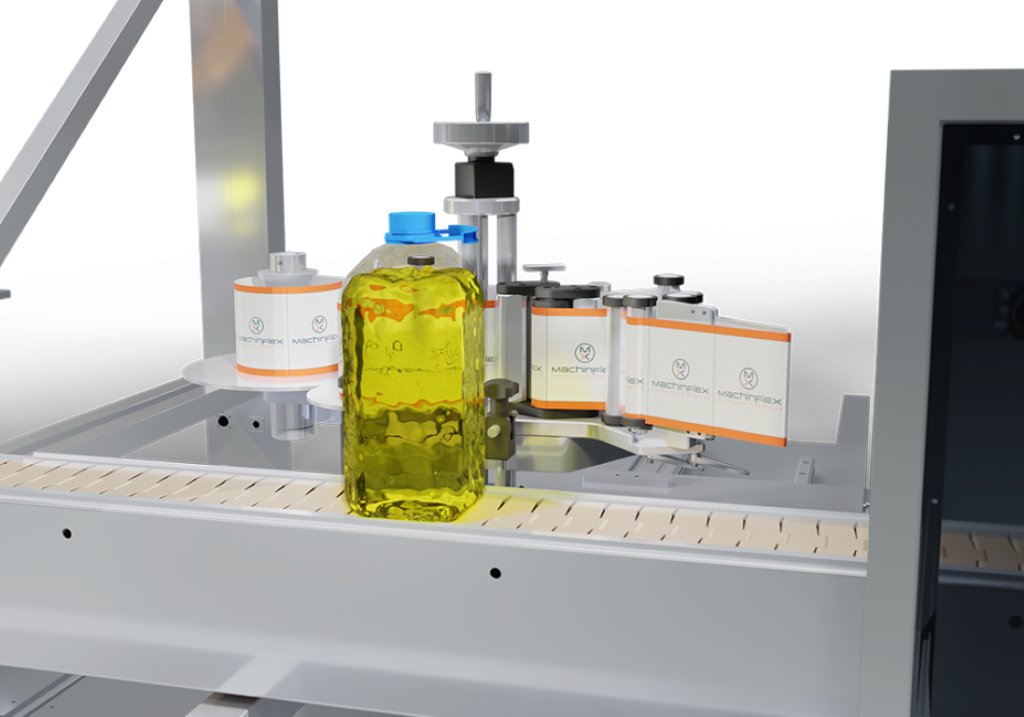

XFR LABELFLOW – HERMA system labeling, servo-driven accuracy and label monitoring.